Old savoir-faire & tradition

Japanese cutting tools quality and sharpness are well-recognized and are rooted in a metallurgic tradition dating back to the “Jomon” and “Yayoi” periods. At that time agriculture emerged and requested new tools.

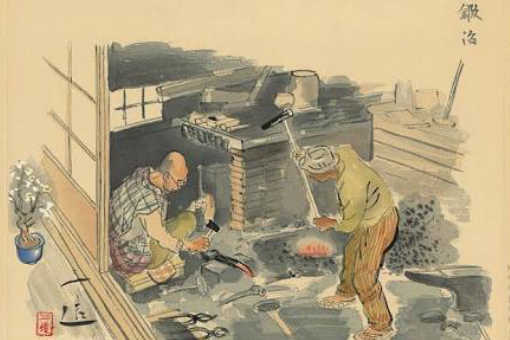

A traditional steel making technique appeared at that moment, using Japanese iron sands to produce high carbon steel or “tama-hagane” in an artisan furnace called “tatara”.

Japanese blade smiths progressively developed their unique savoir-faire and forged swords and blades partly exported to China in the “Muromachi” period.

Progressively replaced by western furnace during the “Meiji” period, the high carbon steel produced today using the ancestral “tatara”technique is extremely limited. It has been replaced by high carbon cutlery steel produced industrially using a process trying to replicate the “tatara” and are known among specialists as “aogami” and “shirogami “ literally blue paper and white paper steels.

With the end of the “Tokugawa Shogunate”, carrying a sword was no longer allowed for the warrior class and sword-making artisans progressively moved their businesses towards professional tools and kitchen knives production as a replacement.

Since fish and vegetables were the central part of the Japanese diet at that time, knives adapted for those ingredients were the most widely used (deba, usuba).

With the apparition and development of a sushi culinary culture the need of slim kitchen knives used to slice fish emerged (yanagiba).

After the second world-war, Japanese consumption of meat increased. Under occidental influence Japanese smiths started to develop and produce new types of Japanese kitchen knives, double bevelled with a western-style handle (gyuto, petty, paring..).